Your location:Home >> Product Center >> Bottom Filling

Bottom Filling

Application scope:

Weisbang 3218 series bottom filling adhesive is a single component, fast curing modified epoxy adhesive designed for CSP (FBGA) or BGA. It is a repairable bottom filling adhesive that can form a defect free bottom filling layer, effectively reducing the impact caused by mismatched thermal expansion coefficients between chips and substrates or external forces, and improving product reliability.

Product features:

1. Single group epoxy adhesive;

2. Fast flow speed; No bubbles, no voids.

3. Good adhesion to the substrate; Has good adhesive strength and reliability

4. Repackable, fast curing, suitable for reflow soldering process.

5. It can be used for dispensing and spraying glue.

6. Smooth glue dispensing, good wetting effect, and the surface can choose between matte and glossy effects.

7. Colors can be customized and selected: black, light yellow, milky white, transparent.

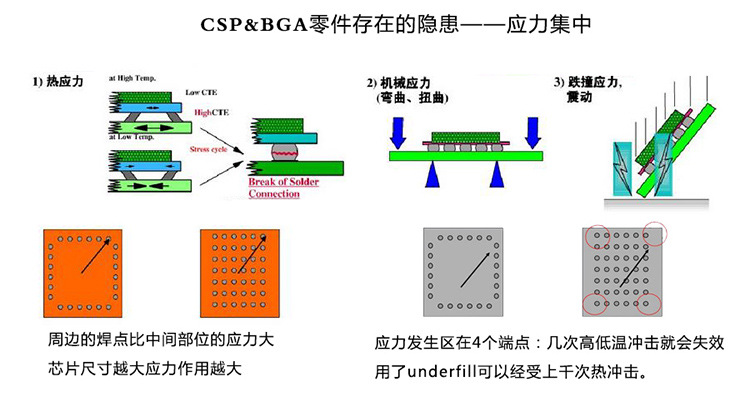

Why use bottom filling adhesive?

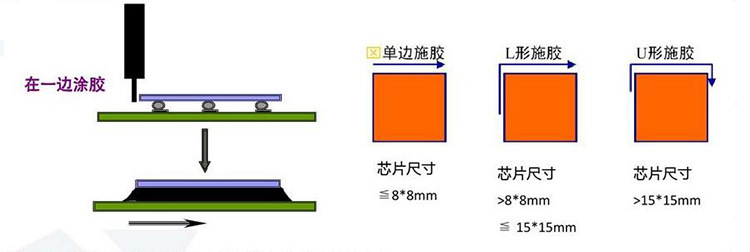

Bottom filling adhesive coating method:

Product attributes:

Product model: VS-3218

Viscosity: 2500-3500 mPa. s

Tg: 67℃

Thermal expansion coefficient: 60-200 ppm/℃

Curing conditions: 3min@150 ℃

Storage temperature: 2-8 ℃

use:

Install the product onto dispensing equipment, which is suitable for many types of dispensing equipment, including manual dispensing machines/time pressure valves, spiral valves, linear piston pumps, and spray valves. The selection of equipment should be based on the requirements of use.

During the device setup, ensure that no air is introduced into the product.

To achieve the best results, the substrate should be preheated (usually at 40 ℃ for about 20 seconds) to accelerate capillary flow and promote leveling.

3. Apply glue at a suitable speed (2.5-12.7mm/s). Ensure that the distance between the needle tip and the edges of the substrate and chip is 0.025-0.076mm, which ensures optimal flow of the bottom filling adhesive.

The usual way of applying glue is to follow an "I" shape along one edge or an "L" shape along two edges intersecting at the corner. The starting point of adhesive application should be as far away from the center of the chip as possible to ensure that there are no voids in the filling of the chip. When applying glue, the length of each glue in the "I" or "L" shape should not exceed 80% of the chip.

In some cases, a second or third application of glue may be necessary on the product.

Repair service:

1. Remove the CSP (BGA) from the PCB board, and any equipment that can melt is suitable for removing the CSP (BGA) in this step. When reaching the effective height (200-300 ℃), use a scraper to contact the bottom filling adhesive strip around the CPS (BGA) and PCB. If the adhesive strip is soft enough, remove the edge adhesive strip. When the temperature is equal to the melting temperature of the solder, and the solder flows out from the gap between the CSP (BGA) and the PCB, use a scraper to remove the CSP (BGA) from the PCB board.

2. Draw in air to remove the melted solder material from the bottom filling adhesive.

3. Remove the remaining bottom filling adhesive from the PCB board. After removing the CSP (BGA), use a soldering iron to scrape off the remaining bottom filling adhesive on the PCB board. The recommended soldering iron temperature is 250~300 ℃. Be careful when scraping to avoid damaging the solder pads on the PCB board.

4. Cleaning: Use a cotton swab dipped in a suitable solvent (acetone or specialized cleaning agent) to scrub the surface. Use a dry cotton swab to scrub again.

matters needing attention:

1. During the transportation process, all transportation items require the placement of cold bags to maintain a temperature below 8 ℃.

2. The glue stored in refrigeration must be reheated before use, and a 30ml syringe requires 1-2 hours (the actual required time may vary depending on the size/volume of the packaging).

3. Do not open the mouth, lid, or cap of the packaging container. The packaging of the syringe tube must be placed under the mouth. Do not thaw by heating, as it may cause partial solidification of the adhesive.

To avoid contamination of unused adhesive, do not pour any adhesive back into the original packaging.

Packaging specification: 30ML/syringe

Storage conditions:2-8℃